Portugues

Portugues |

Product and process reengineering |

| Home | About Us | Product and Tools designs | Machines designs | Process Diagnostics | Contact |

|---|

| Plant Startup | Recycling

Technology | Polymeric composite | Innovaitions | Profiles Extrusion Die/tool | tooling |

|

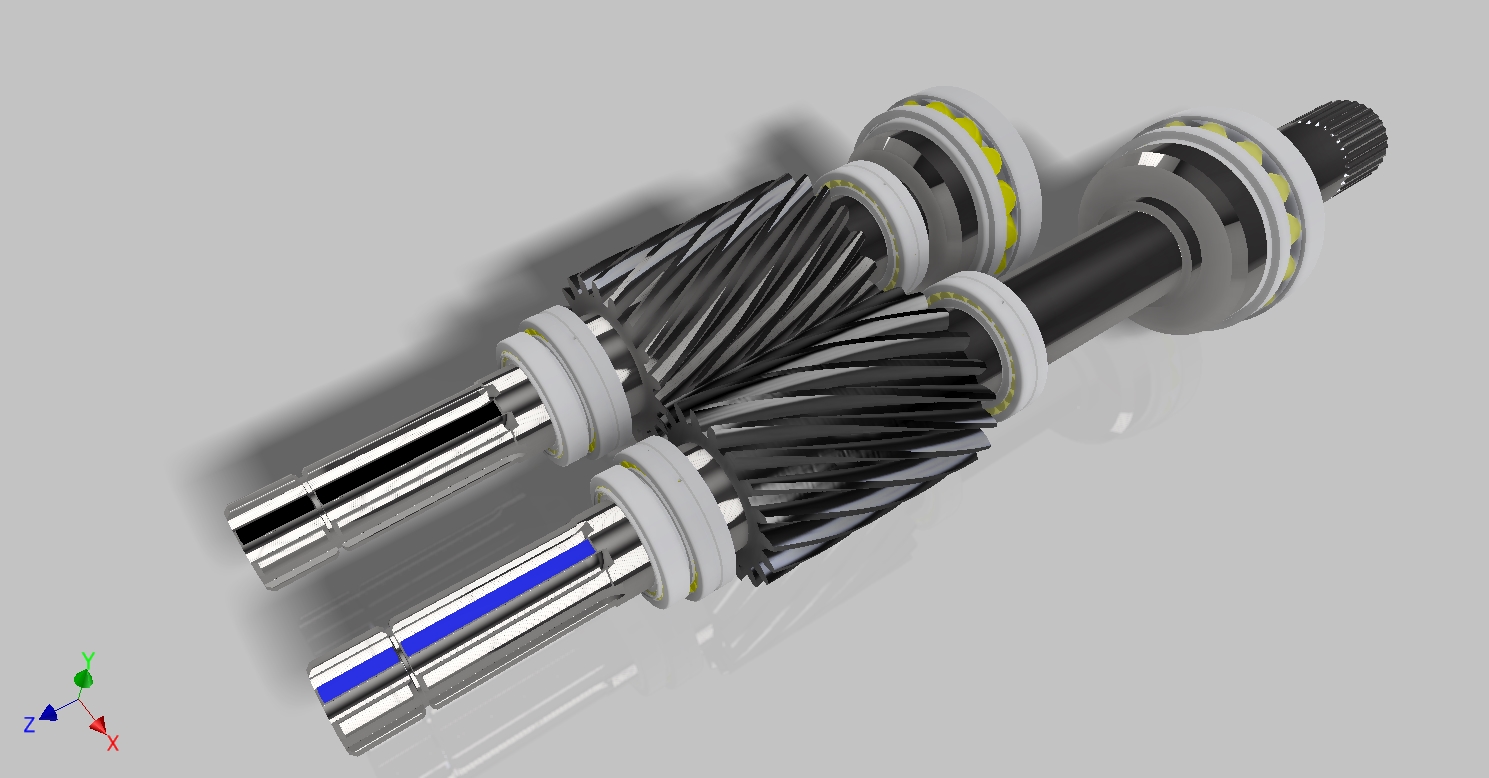

From the idea to the launching on market!! Is our thing!!!. Develop

of industrial products has a well-known script by D&D, since the

days of manually designed templates (before the CAD/CAM technology)

made of wood or resin, we conduct numerous developments of products for

various fields, such as construction, manufacturers of cars and

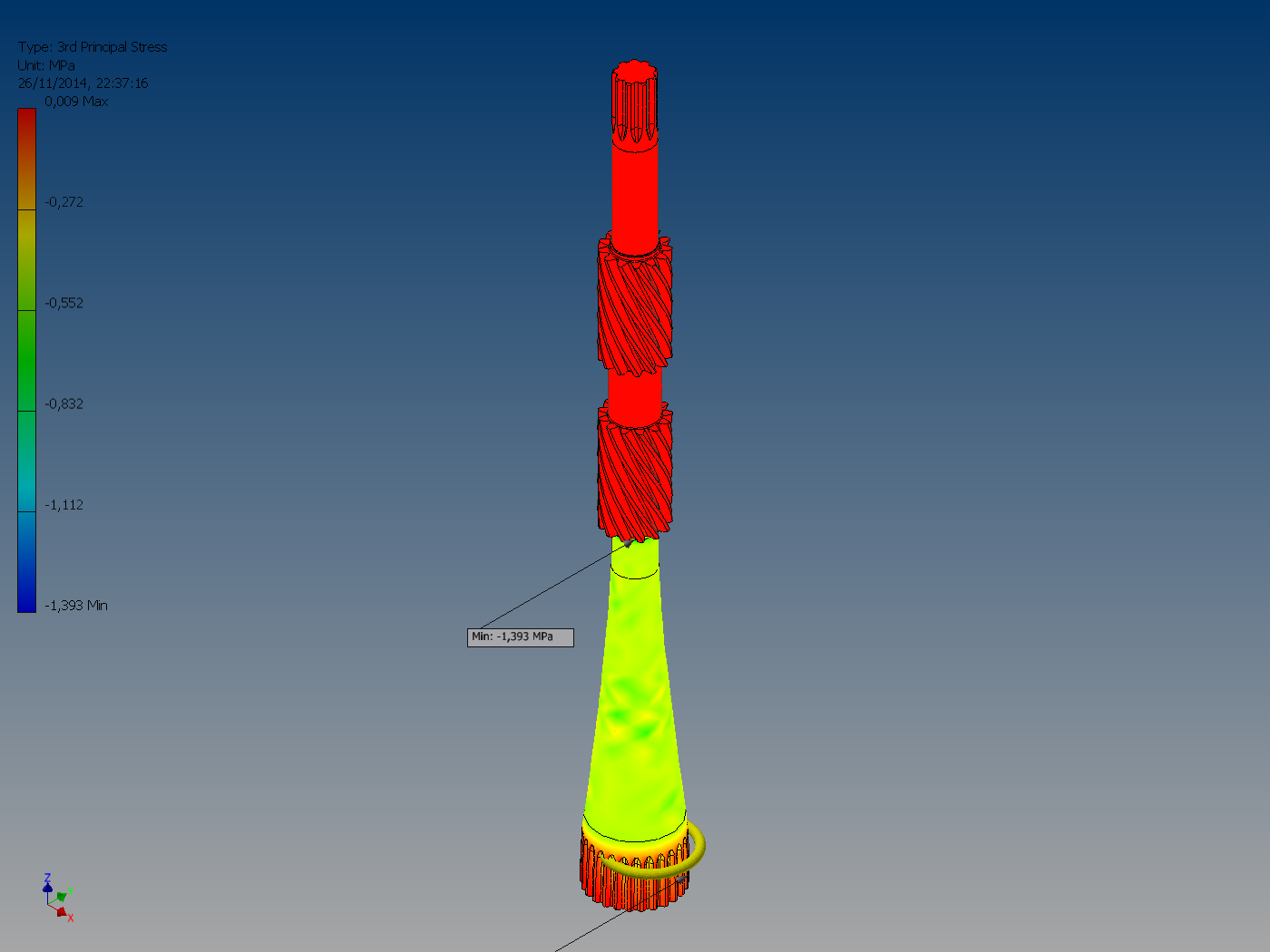

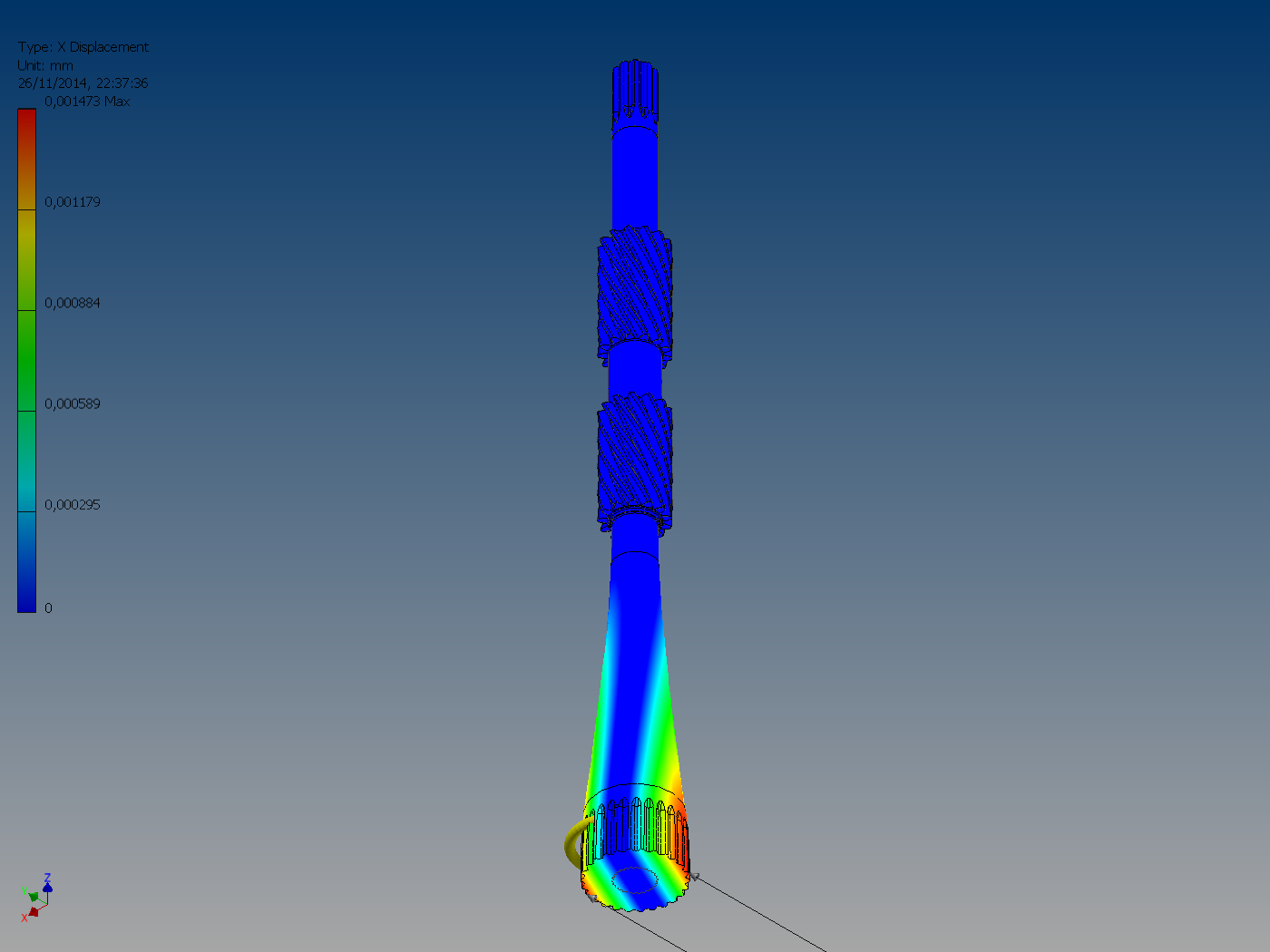

trucks, household appliances, agricultural machines. We can help at every stage of development: a. First step begins by seal confidentiality agreement, our focus is the client and his safety, your success is ours. b. After to know the idea, we can analyze it using our vast experience present ideas and suggestions for improving the performance, where possible, once this analysis is made, proceed with 3D modeling, virtual simulations of stress analyses, efforts and movements.

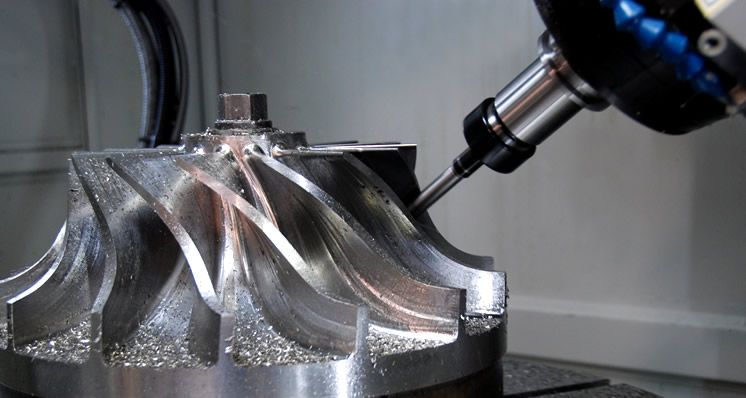

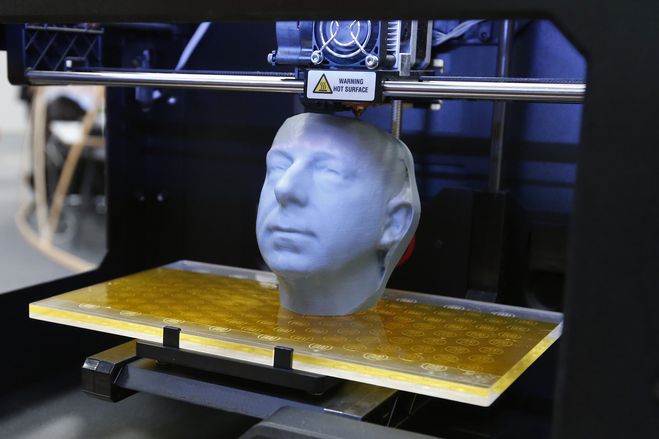

c. The

second step, after completed these settings and adjustments of the

design, is producing some physical prototypes for field testing and

simulation application. i. There are several ways to produce the prototypes, CNC milling or 3D printers (in several processes indicated according to the needs of the prototype).

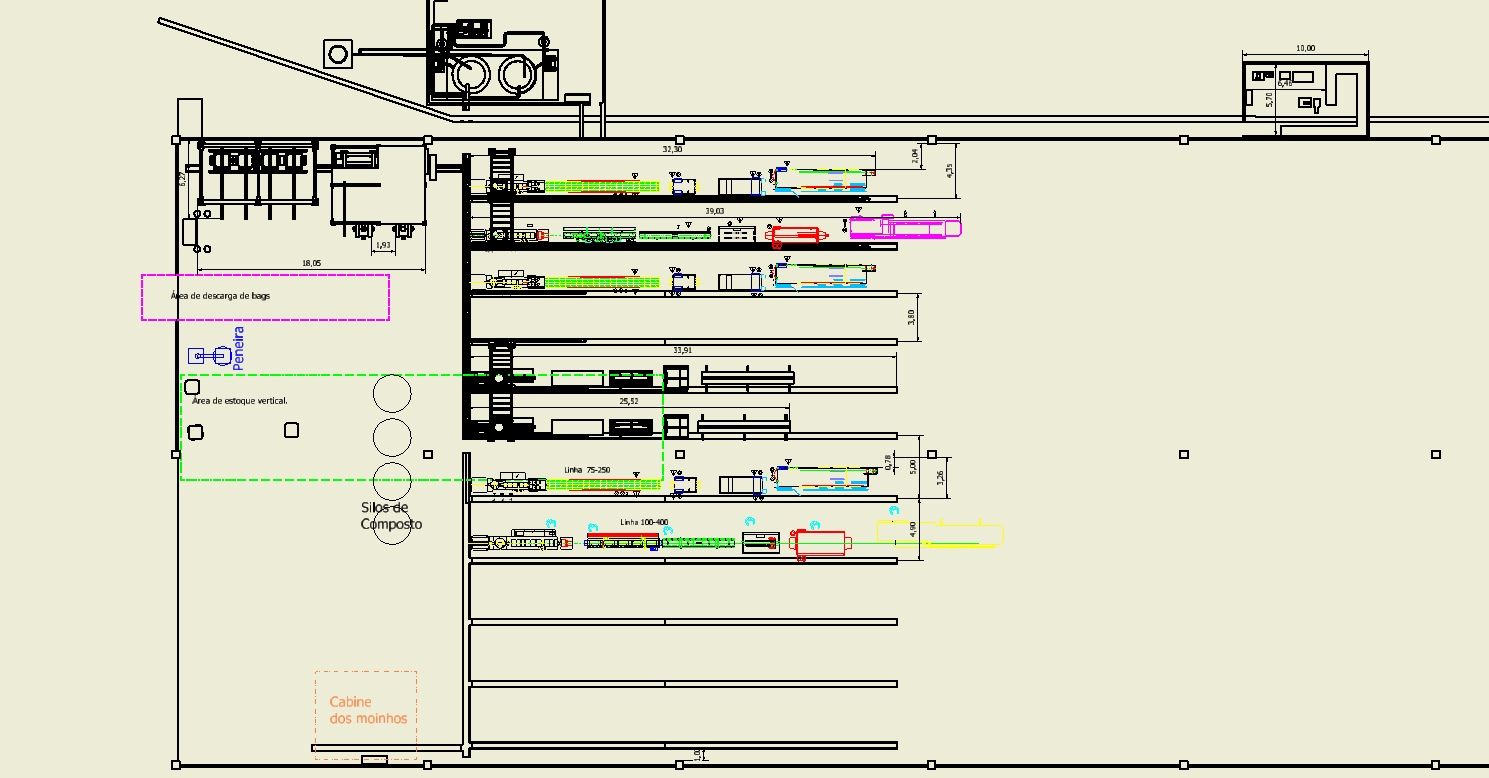

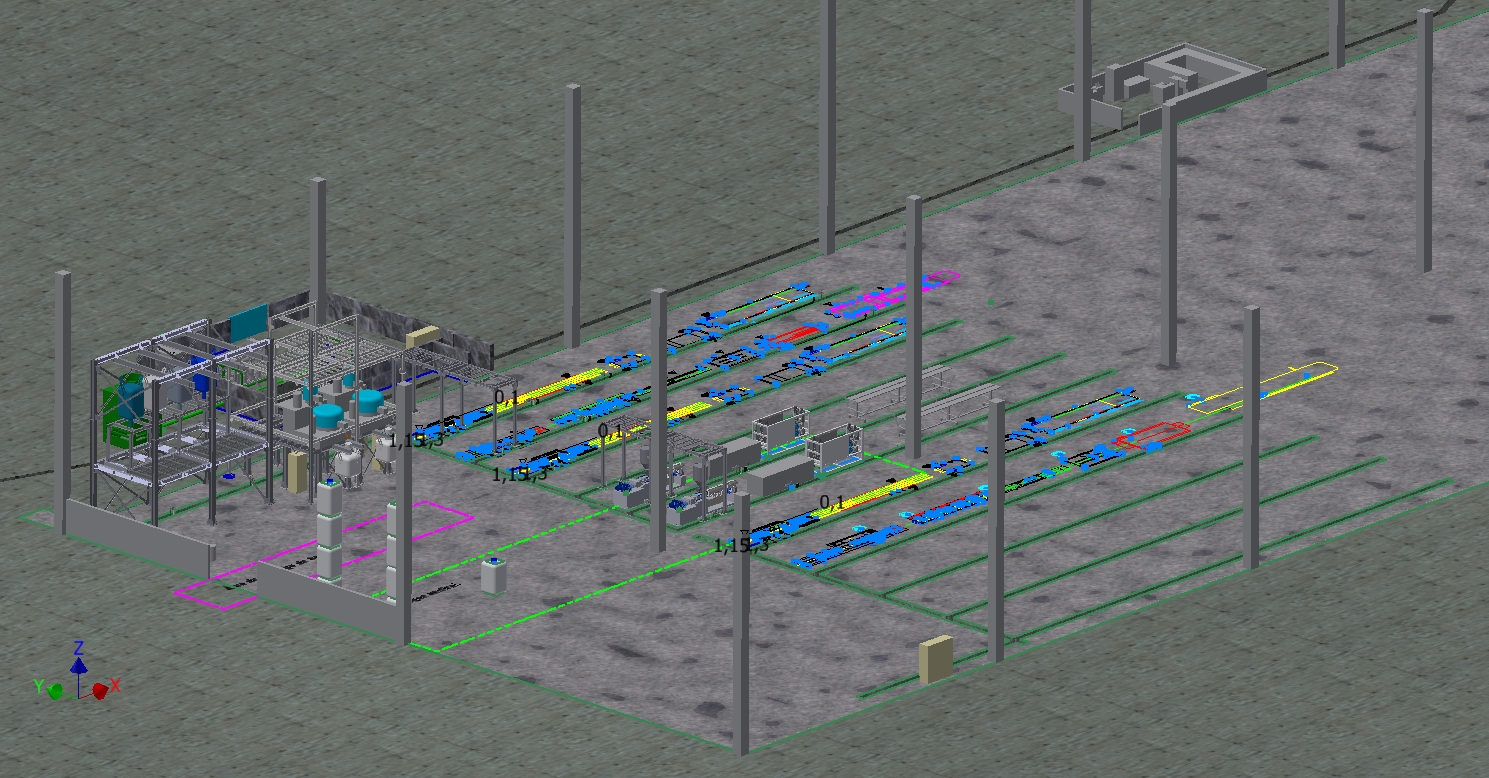

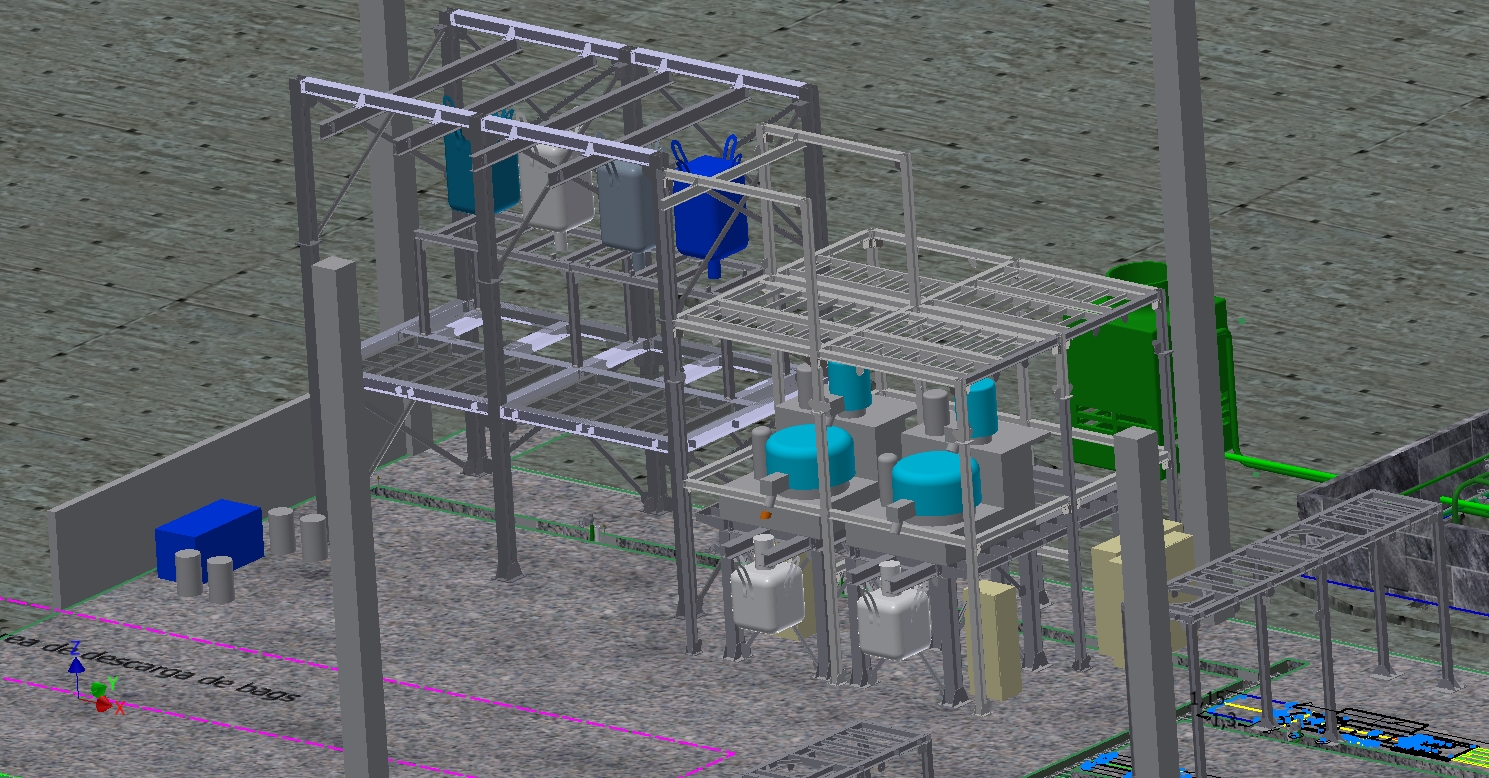

d. After tests and final corrections, can design the productive process and tooling. e. At this point we can already define the layout of the production line, dimensioning inputs and services to do the final layout and design of facilities.

f. The following steps are;

i. Quotations and purchases of equipment.

ii. Site preparation and do electric and hydraulic installations, compressed air, etc.

iii.

Try out of all systems.

iv. Try out production equipment and tooling.

v. Startup of the line. With production personnel training.

vi. Fine tuning and fitness to standards.

vii. Approval

of the production system by the qualifier organization. In all these steps the D&D has experience and knowledge to lead or assist the deployment. |

| To send an e-mail queries on this subject click the link: |

| e-mail to D&D Enterprises |

|

Machines and Equipament |

|

|---|

| D

& D Enterprises Consultoria Industrial Eirele.

+5511999798292

comercial@danddenterprises.com |