| Home |

About

Us |

Product and Tools designs |

Machines

designs |

Process Diagnostics |

Contact |

|---|

| Plant Startup | Recycling

Technology | Polymeric composite | Innovaitions | Profiles Extrusion Die/tool | tooling |

|

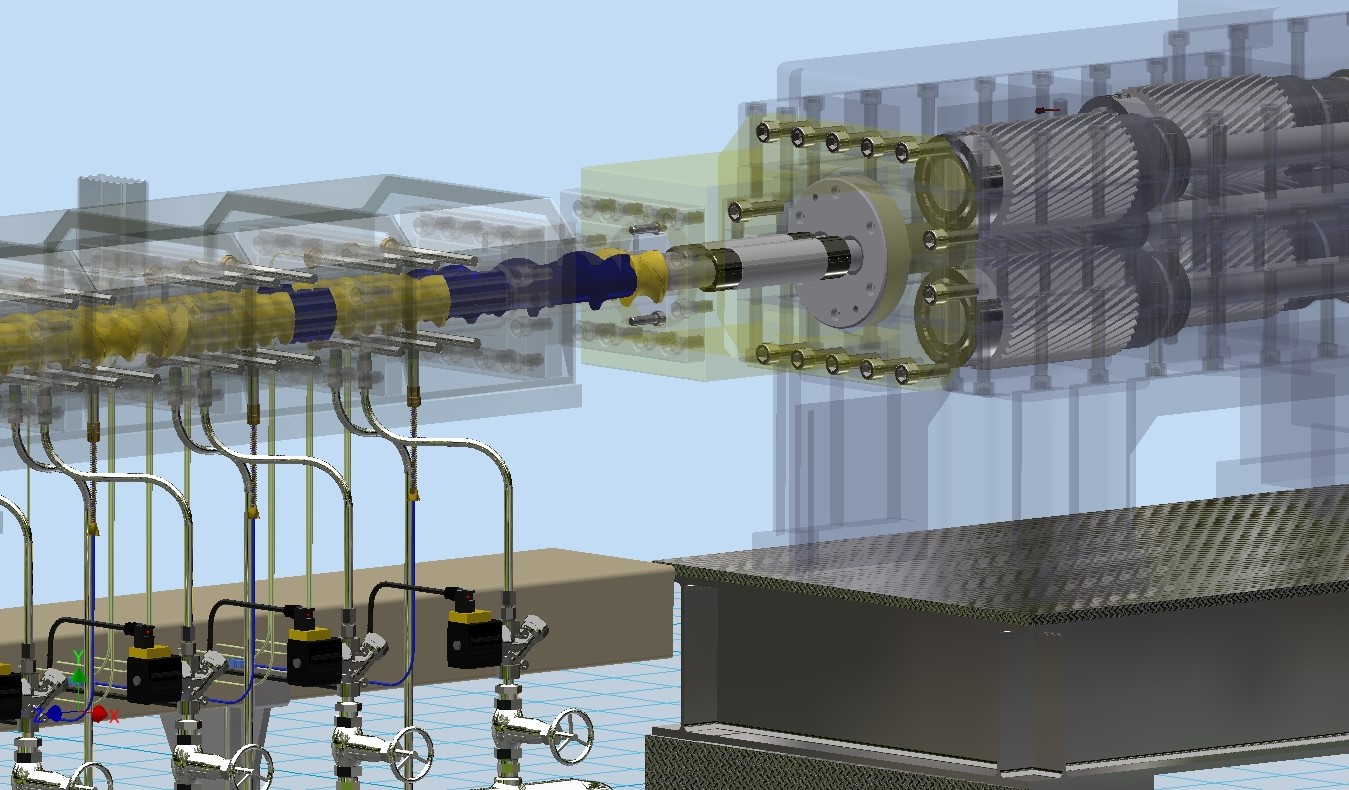

Since the late 70 's we

design machines, devices, or components for production of plastic

products. We

started the career at a time when industrial production solutions were

not available as today, which is just search Google to find the

appropriate equipment, everything had to be invented and developed. Search for books, trapping

in the library. Consult with how known. Roll up your sleeves and DO! This

hard experience, consolidated by long years of improvement in knowledge

of mechatronic systems, learning about polymer processing and the huge

amount of developments realized during all this time, made us able to

accept great challenges. Our portfolio of experience

and knowledge in design and construction of machines covers the

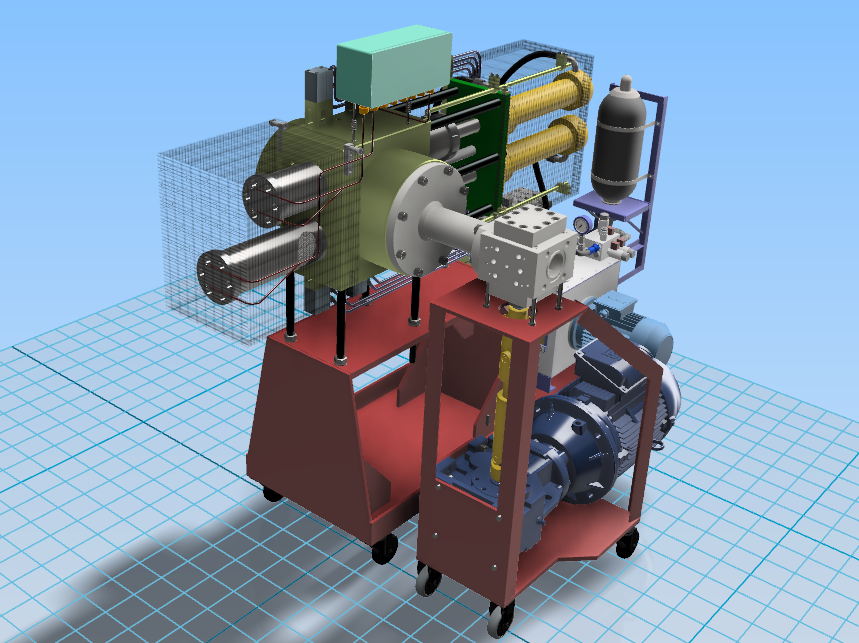

following areas (not exclusively): Design and construction of : 2) Twin parallel counter rotating extruder. 3) Twin parallel co-rotating extruder. 4) Twin conical counter rotating extruder. 5) Complete downstream for profiles. 6) Complete downstream for pipes. 7) Complete downstream for pelletizer, water stand, water ring or underwater. 8) Auxiliary devises as crashers, silo, loaders, guillotine, centrifugal dewatering, vibrating sieve, etc. Some of the projects we do integrate development of models and special designs, containing secrets that are not common knowledge.

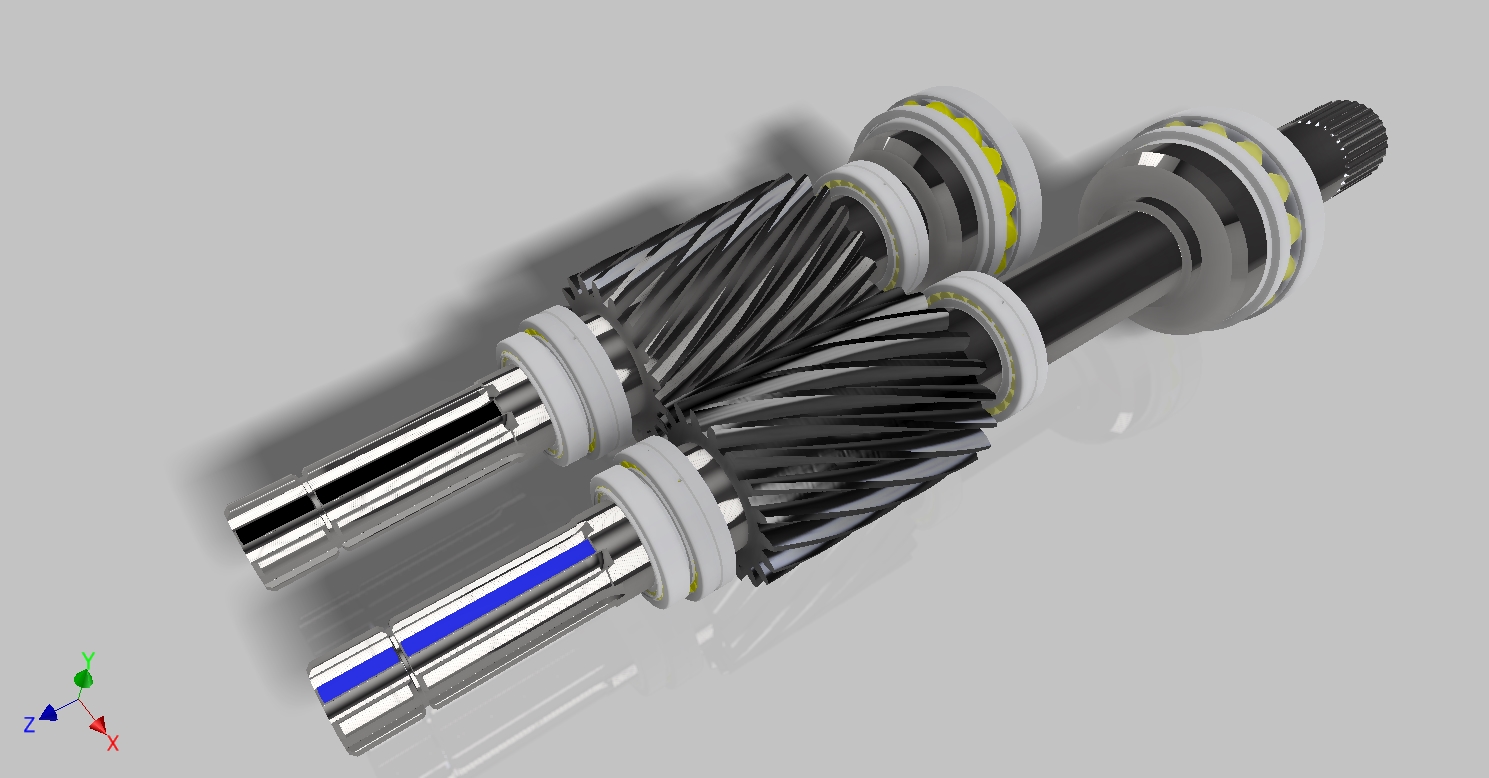

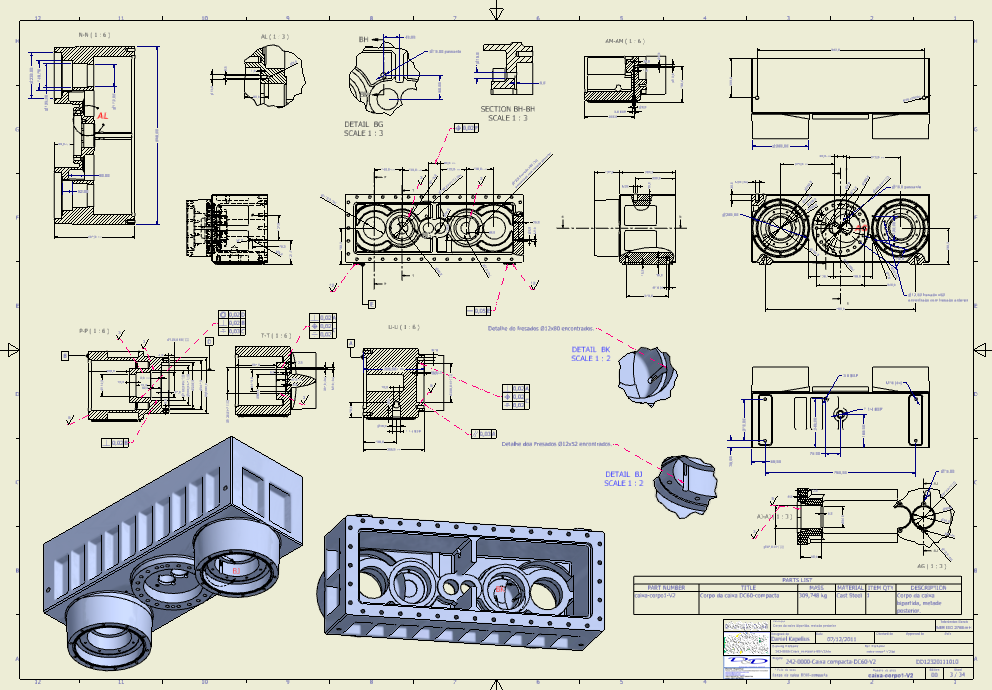

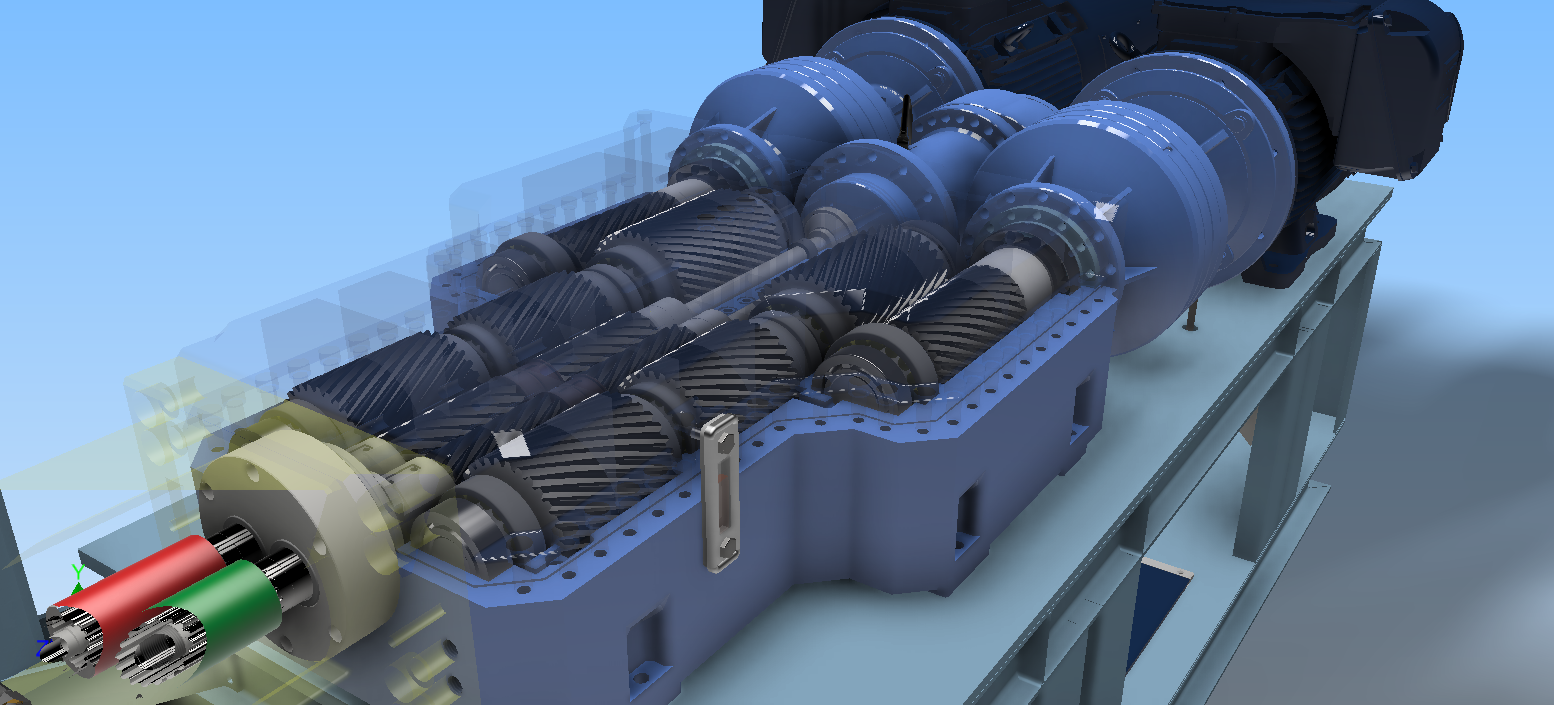

Very

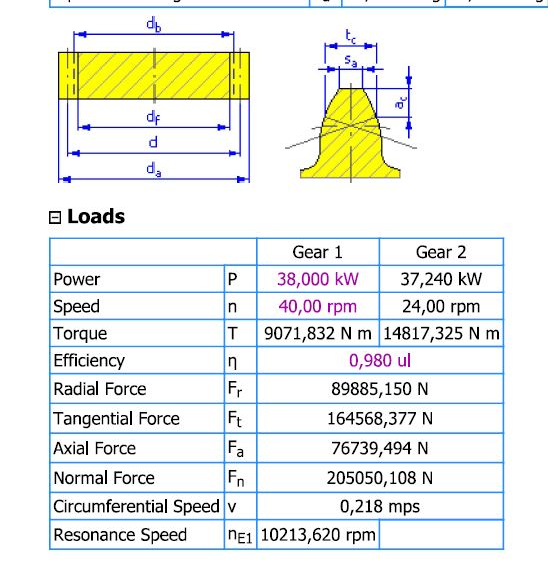

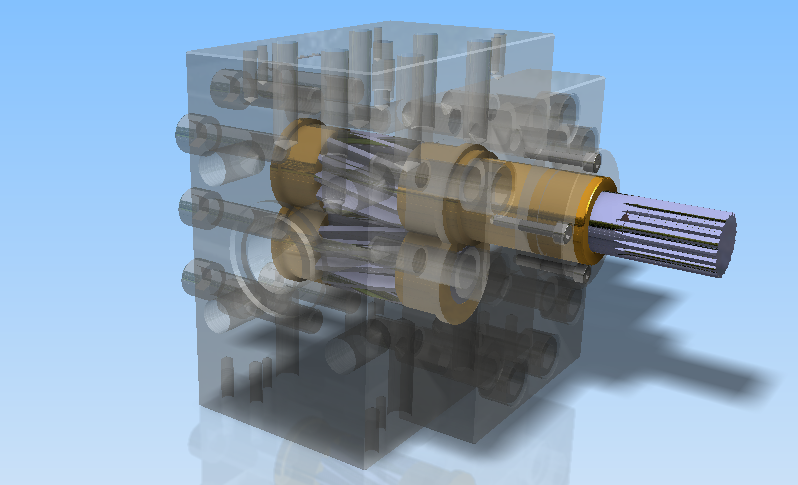

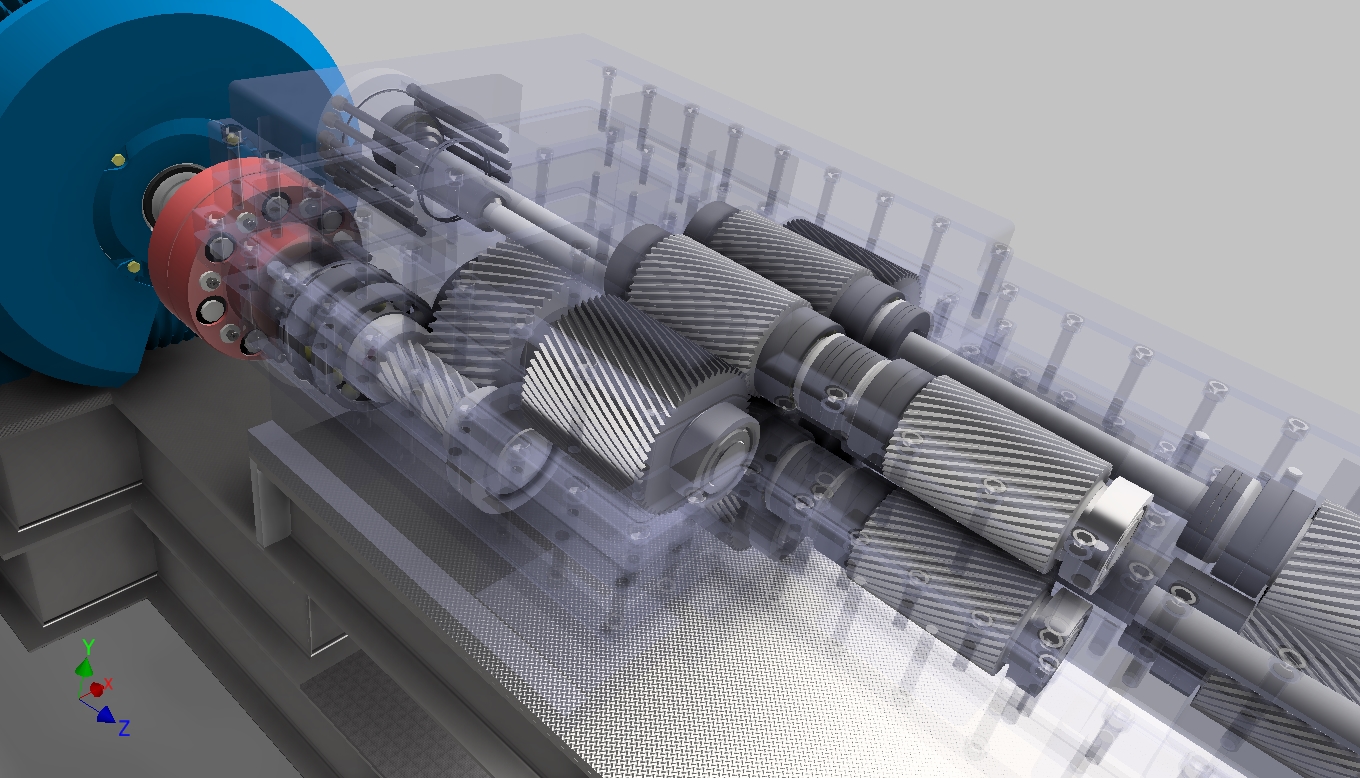

important and difficult case is the transmission gearbox of a parallel

twin screw extruder, either the co-rotating or counter rotating. By

difficulty to transmit high torques to the two screws, having distance

between centers very small. In these two cases have developed a design own, unpublished, and giving excellent results and performance, with torque 20% higher than normal.

The D&D has great expertise in this type of project, in the case of twin screws, the gearbox is the soul of the machine.

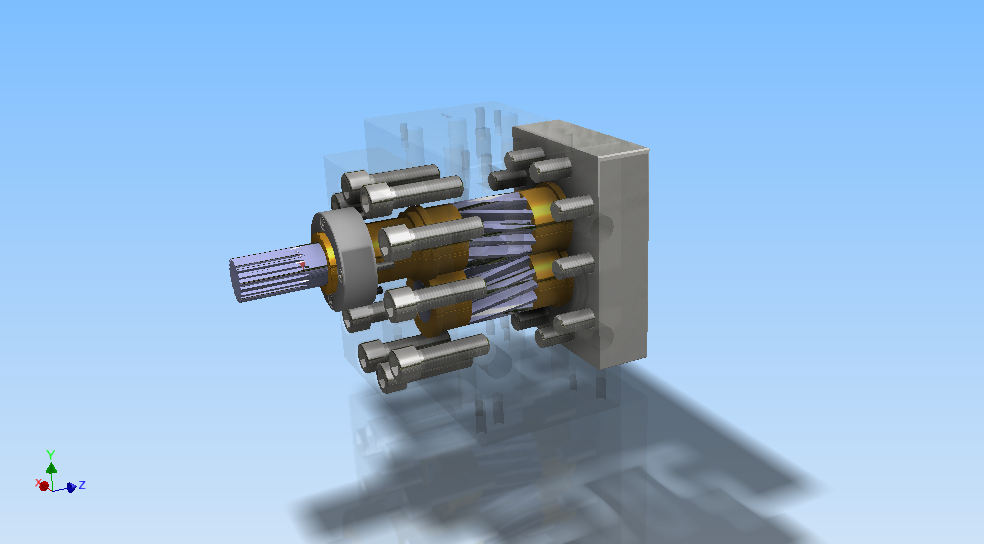

Gearbox for twin parallel extruder counter rotating, this model is bi

tangential, for higher torque .

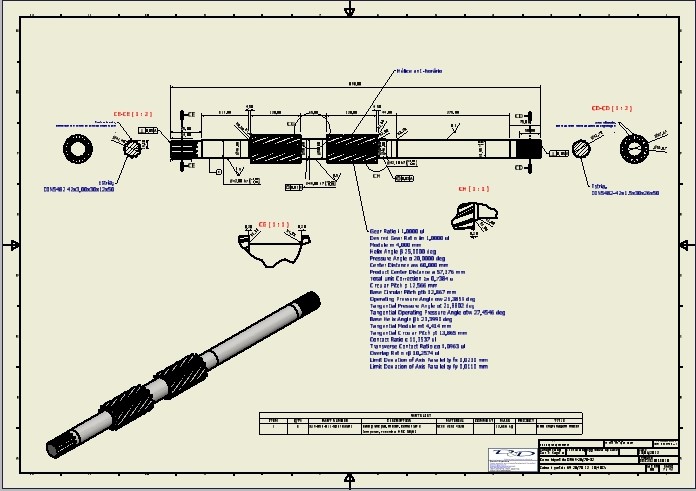

This

is a sample report of the result of a set of gears, loads and the

material used in the test, and the positive result! With safety factor

> 1.2

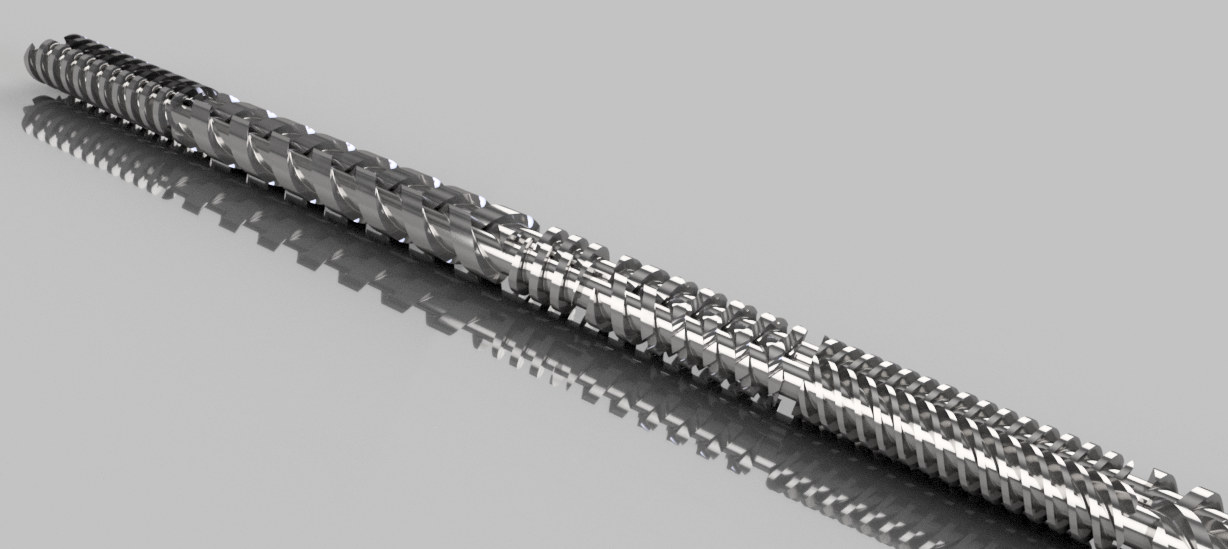

Another

specialty of our company is extrusion screw design, for double screw

extruder, mainly counter rotating, parallel or conical. There are many variables that make up the equation: the specific conditions of work such as rotation, temperature, load loss of the die/tool, the type of polymer, rheology and his sensitivity to stress from process and even the changes caused in rheology by additives, fillers or formulation.  We

have made many designs of screws that are running today on several

machines in Brazil, and others countries.

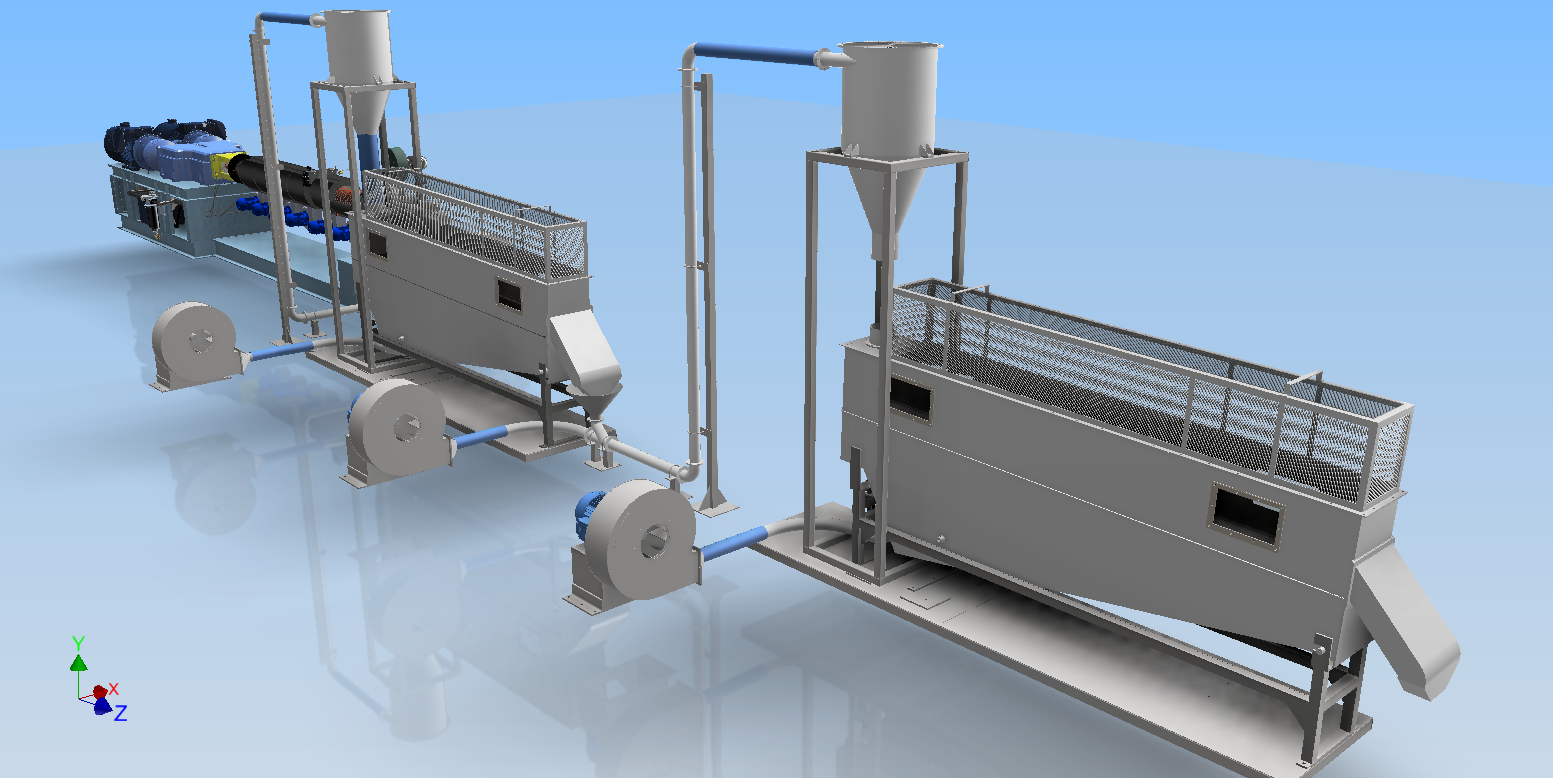

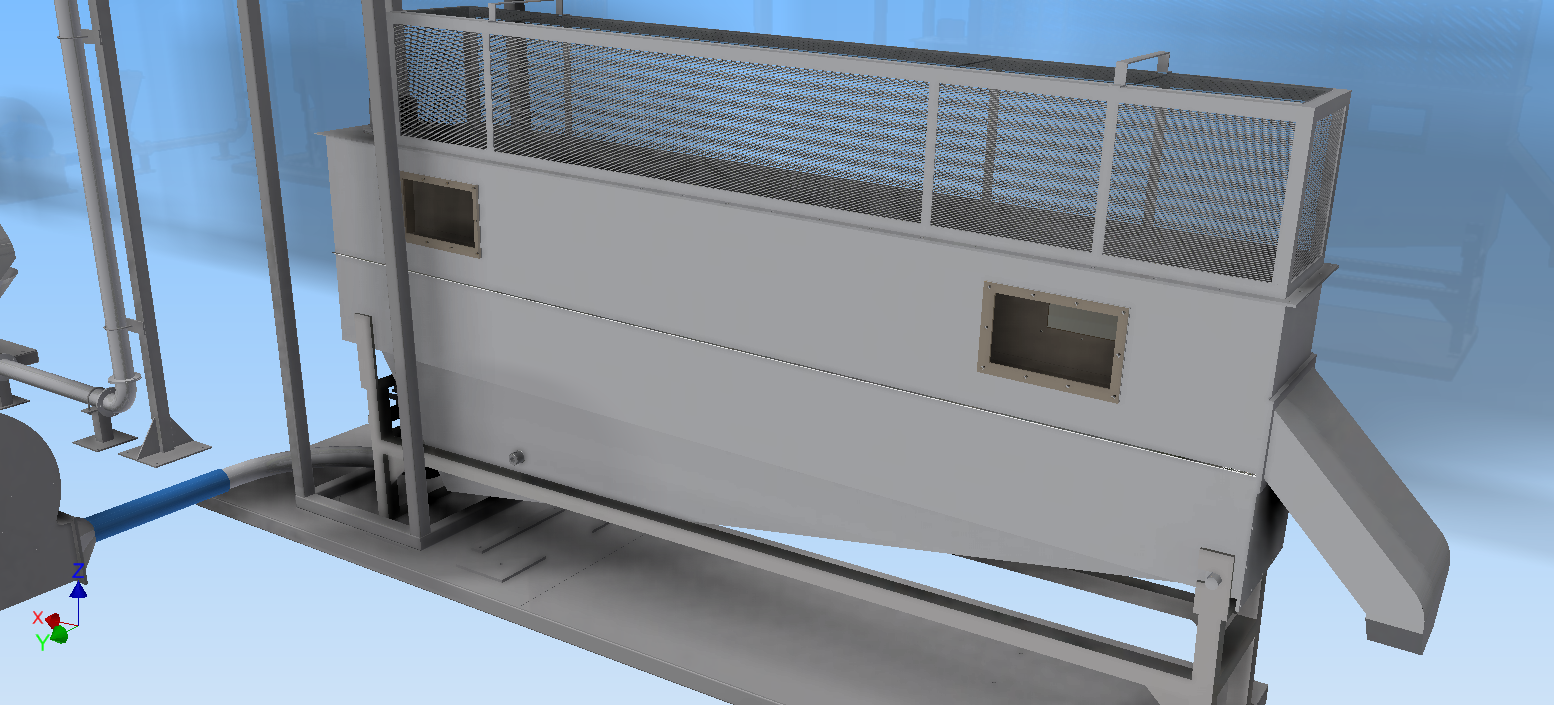

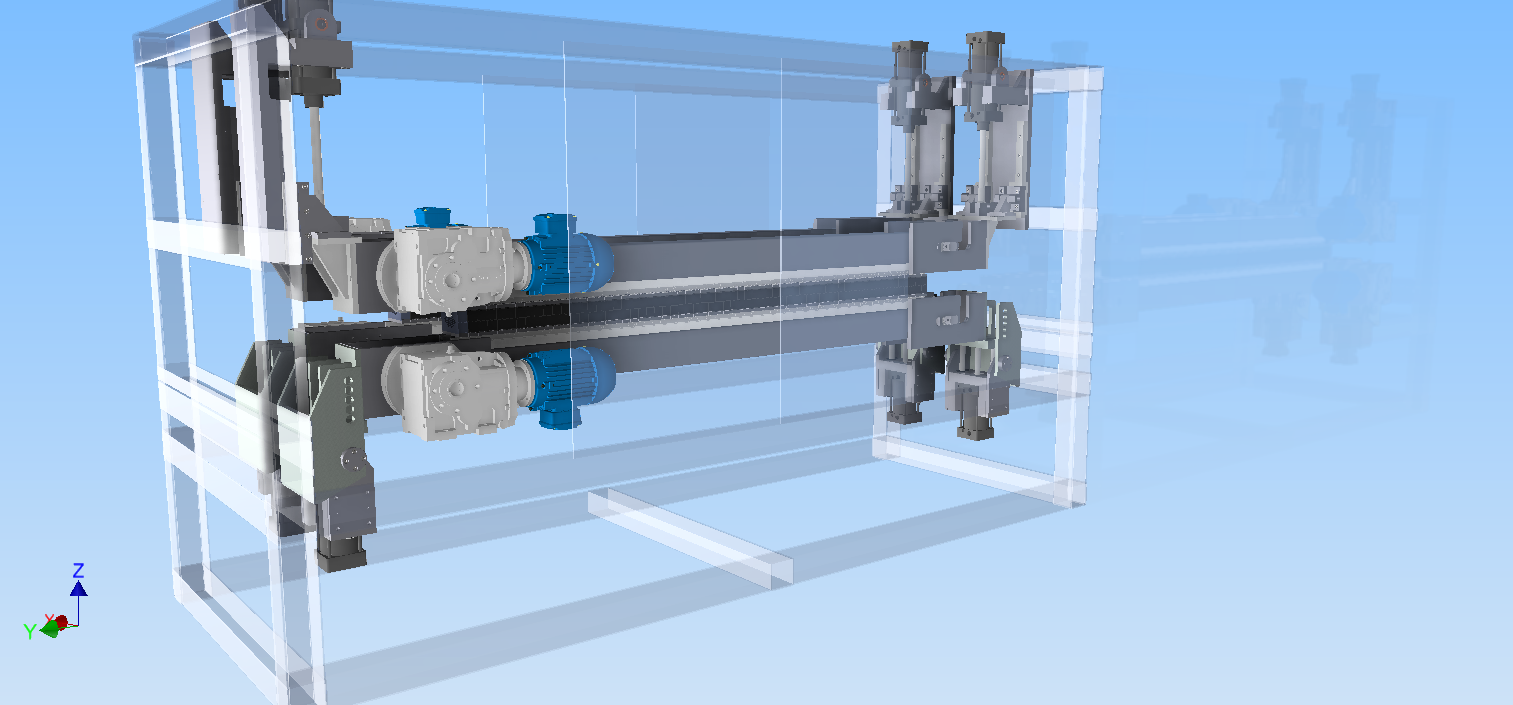

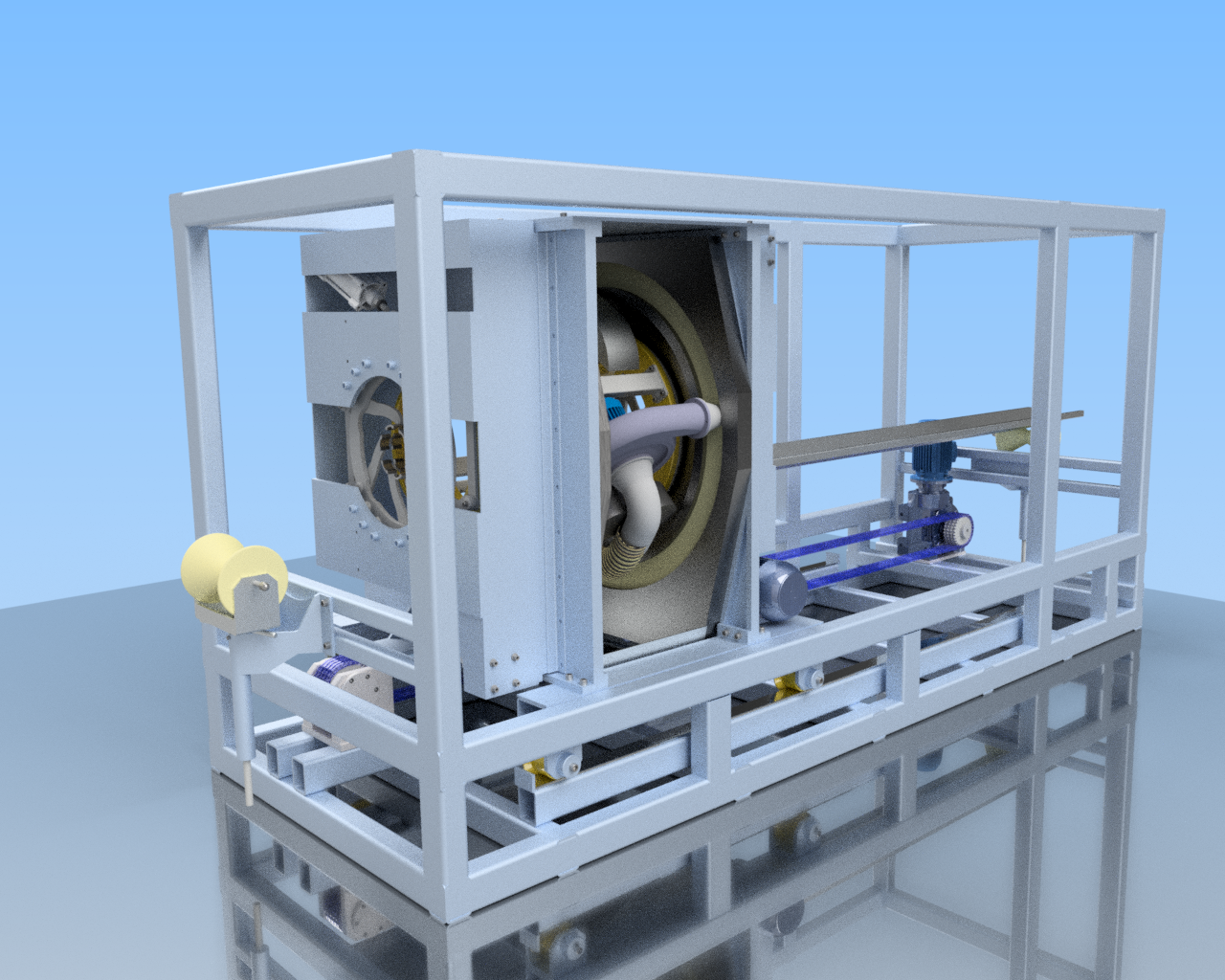

Some examples of projects for other components: Dry granulation line, hot cutter, with dual fluid bed, up to 1200 kg/hour

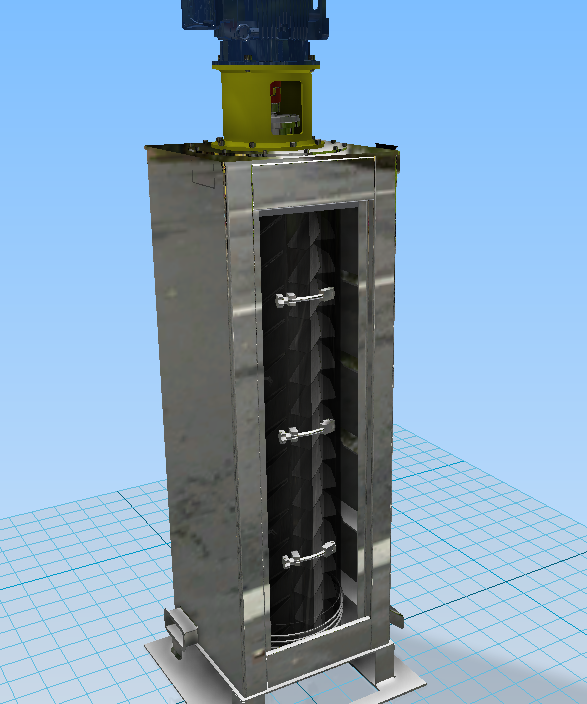

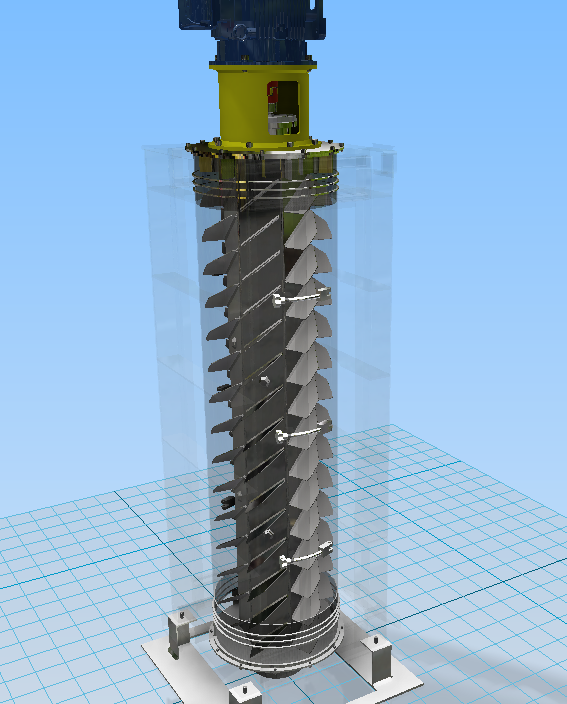

Granulation line with water ring, vertical dewatering centrifuge to 1200 kg/hour.

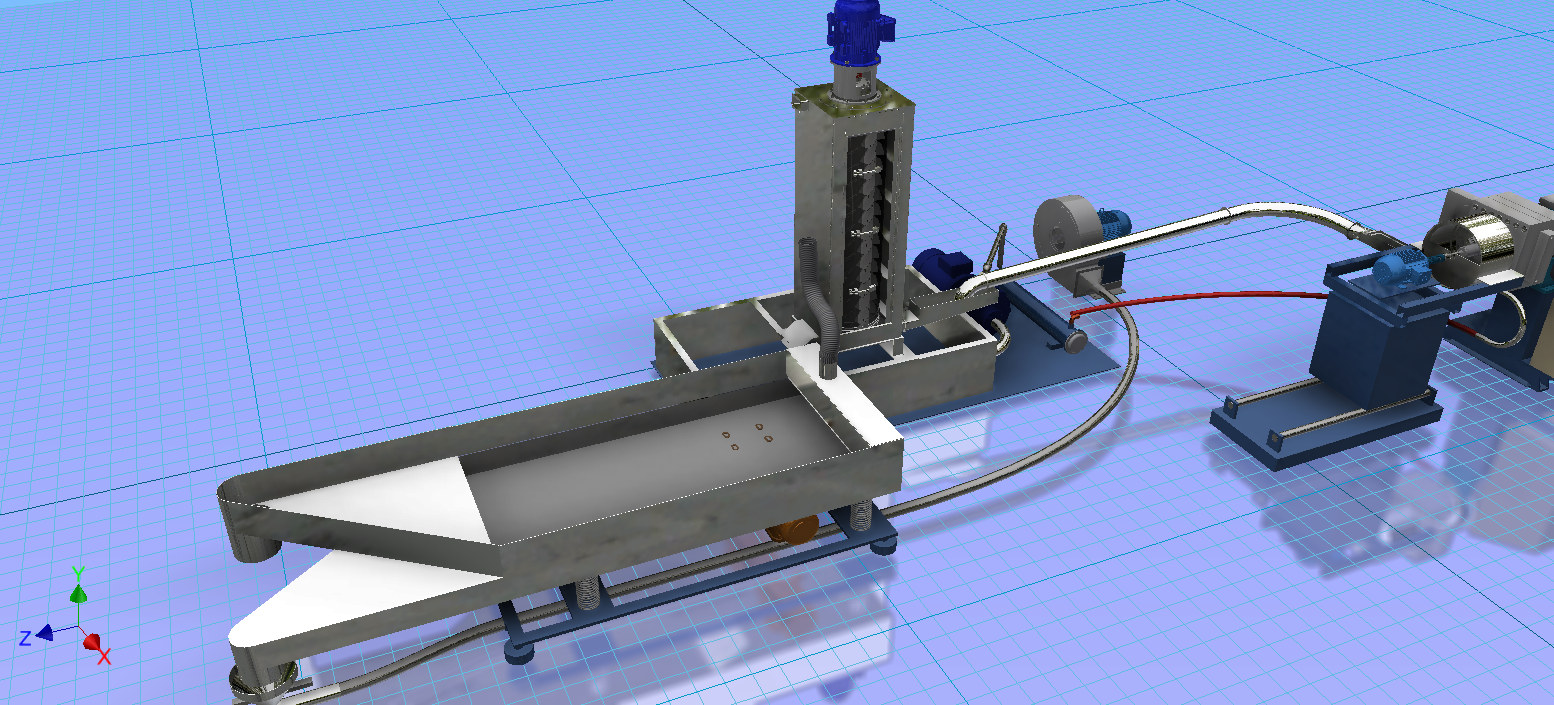

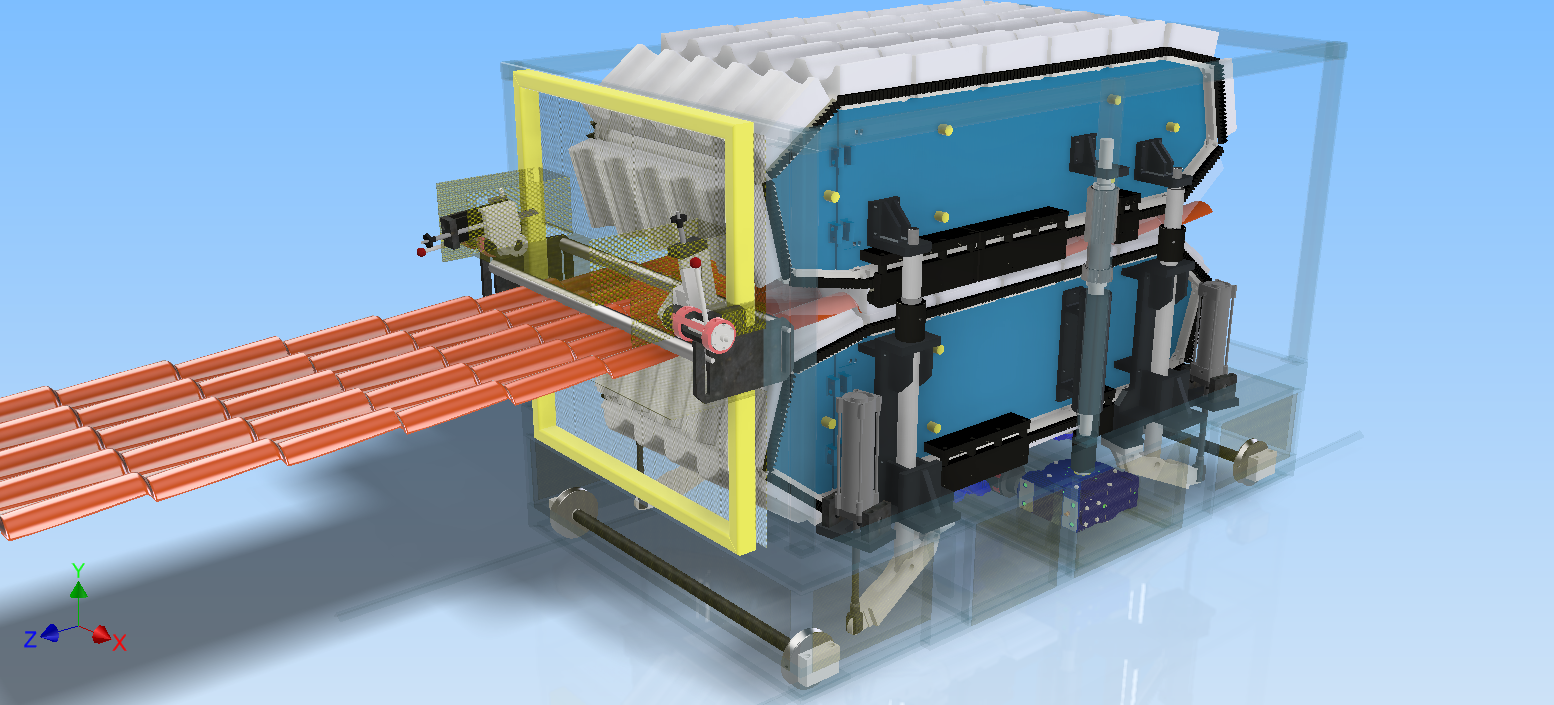

Pull off caterpillar type, compressed air floating without columns, for profiles, boards or pipes

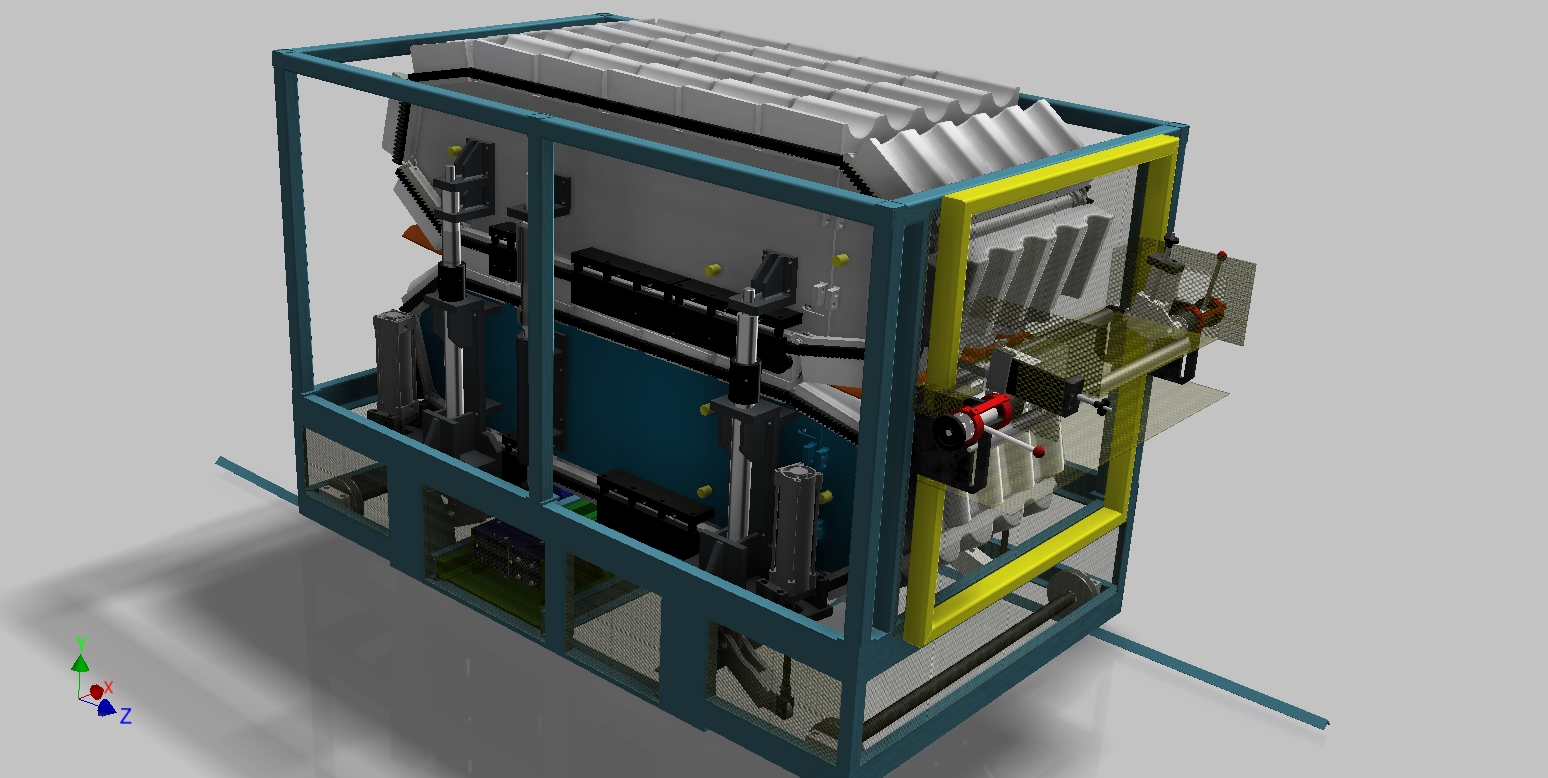

Conformation for

tiles in line for PVC tiles, ABS, acrylic, PP and other composites.

Last release February 2018,: Planetary cutter for tubes from 40mm up to 400 mm!

These

examples are only a sample of the ability of achievement acquired

during these 40 years. We cannot show details or data from projects by

maintaining the confidentiality with our clients, which is sacred to us. The D&D Enterprises is

proud to maintain ethical and responsible conduct with their customers. The

talent and creative genius are ours, and we can use and abuse them for

all future projects, but the intellectual property of already made,

belongs to the client that the acquired. D&D offers different

forms of contract to develop their projects. With exclusivity and

confidentiality, with licensing and Royalty system, or just fees. Come chat with us, we will have great

pleasure in getting to know your idea and offer our solution. |

| Home |

About

Us |

Product and Tools designs |

Machines designs |

Proscess Diagnostics |

Contact |

|---|

| To send an e-mail queries on

this subject click the link: |

| e-mail to D&D Enterprises |

|

Machines and Equipament |

|

|---|

| D

& D Enterprises Consultoria Industrial Eirele.

+5511999798292

comercial@danddenterprises.com |

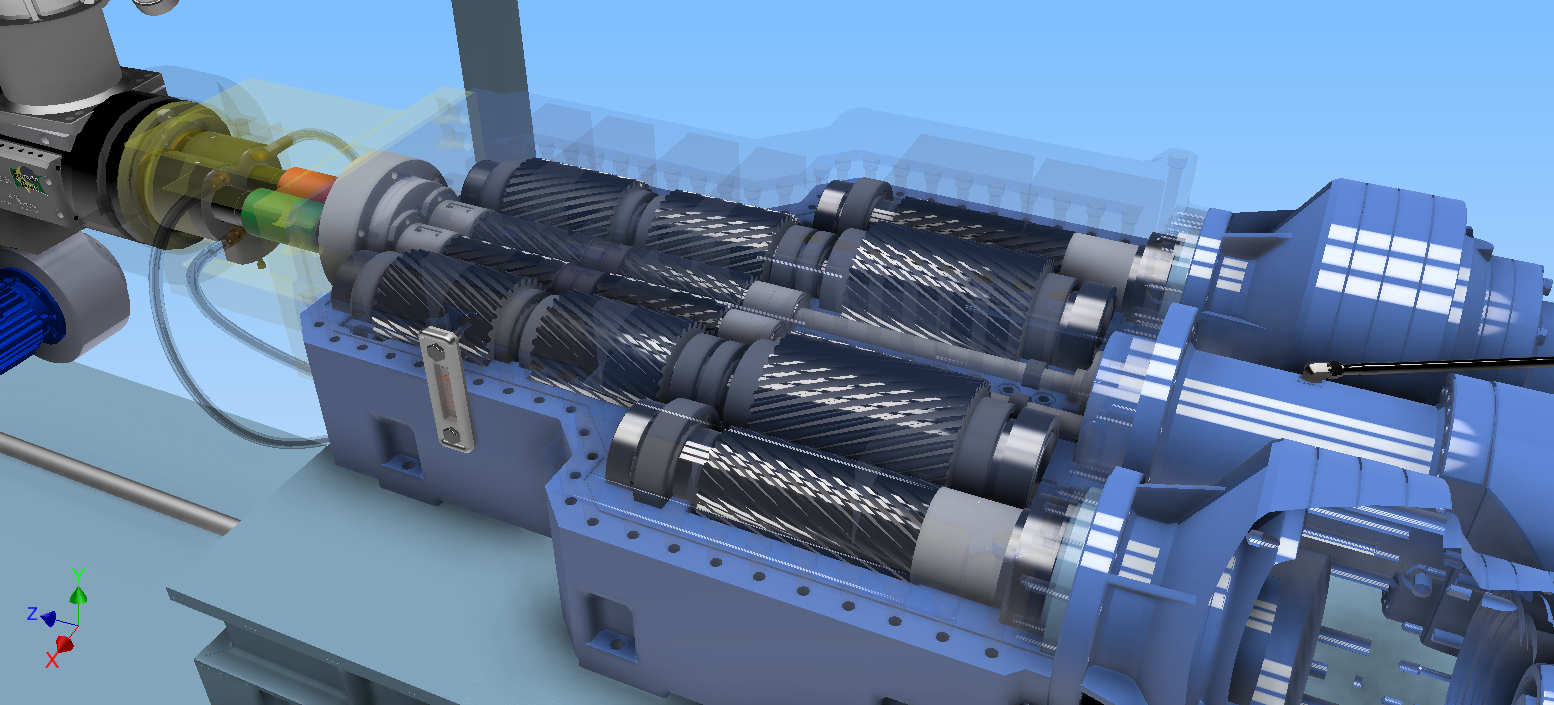

Gearbox quadri-tangential to co-rotating extruder

Gearbox quadri-tangential to co-rotating extruder These

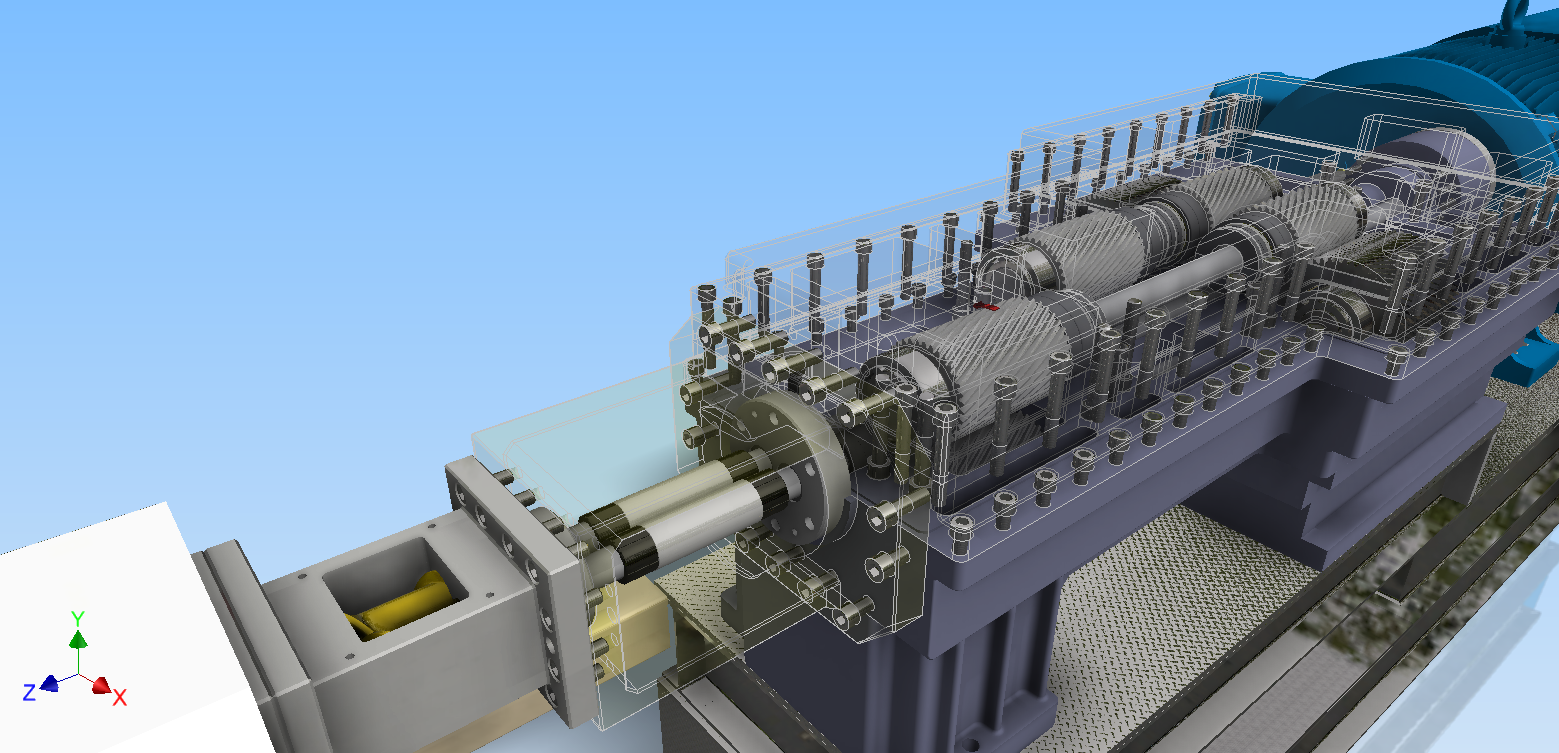

projects are carried out making use of the most modern software

engineering resources, all components are severely tested in simulation

of STRESS-STRAIN ANALYSIS, to ensure the correct choice of materials,

heat treatment and life more than 10 years.

These

projects are carried out making use of the most modern software

engineering resources, all components are severely tested in simulation

of STRESS-STRAIN ANALYSIS, to ensure the correct choice of materials,

heat treatment and life more than 10 years.